PurOtreat (PDF)

Fresh product coming from the field is covered with mold spores and bacteria. The mold spores and bacteria generally have not anchored onto the fresh product but the conditions for forming an irreversible biofilm are in place. The PurOtreat system was initially developed to control molds on blueberries but ozone gas treatment was found to be ideal for killing molds and bacteria on blueberries, strawberries, kiwis, oranges, lemons, melons and a variety of other fresh products. Treating fresh produce with the PurOtreat system means reduced fresh produce shrinkage and extended shelf life. At the time we were experimenting with PurOtreat we discovered it was ideal for dry sanitizing the equipment used to move dry product. For equipment that cannot get wet, the PurOtreat is a solution.

The PurOtreat system uses our standard Purotecs ozone generator. Ozone gas is sent from the generator to a chamber. A conveyer moves fresh produce through the treatment chamber. Fresh produce is treated for approximately 30 to 60 seconds. A continuous ozone monitor provides feedback to the generator for automatic dosage control required for exact treatment. Products are treated as soon as possible after harvest and placed in treated containers and treated storage facilities. A variation of the PurOtreat system is to use a pre-cooler room as a chamber and expose the fresh produce to lower ozone concentrations for longer time periods. In a similar way, PurOtreat sanitation gas is directed into, onto, or through equipment that cannot get wet but needs to be sanitized.

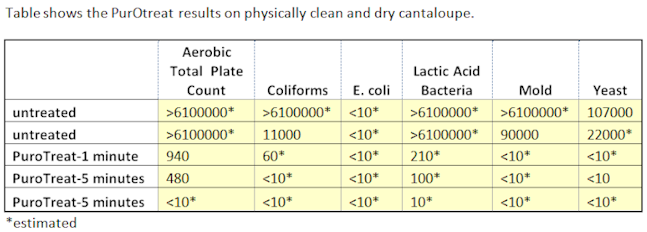

On physically clean and dry cantaloupe, a notoriously difficult product to clean, the PurOtreat resulted in a greater than 4-log reduction in mold, yeast, and bacteria. The table below shows the laboratory data.